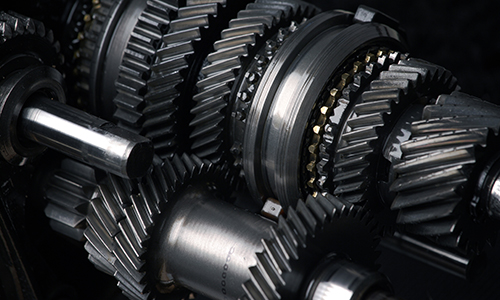

WPS offers a comprehensive range of solvent-free epoxy composite materials designed to repair and prevent the common failures associated with mechanical power transmission. Our cold-applied epoxy materials provide a rapid and reliable alternative to welding and machining techniques, which are typically required for conventional repairs.

Worn and damaged shafts can be repaired in situ, minimizing downtime and reducing production costs. Bearing housings can also be repaired using our erosion and corrosion-resistant metal repair materials, offering in-situ and emergency repair solutions that extend the lifespan of your equipment and return machinery to service in a fraction of the time.

Our cold-curing epoxies are formulated to offer long-term erosion and corrosion protection and are capable of bonding to a variety of metallic surfaces, including cast iron, aluminum, and steel.

WPS’s range of metal repair composites will:

- Repair and rebuild damaged and scored shafts

- Protect exposed areas from corrosion

- Repair oversized keyways

- Protect surfaces from corrosion pitting

- Rebuild damaged bearing locations in situ without machining

- Modify existing bearing seats

- Repair or replace low-friction bearing surfaces

- Reform ball joint housings

- Realign pins into oversized housings

- Reseat bushes into damaged locations

- Repair elongated coupling bolts/dowel locations

- Rebuild drive faces